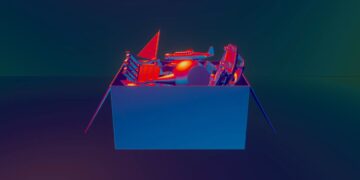

Amazon has developed a brand new warehouse robot that makes use of contact to rummage round cabinets to search out the suitable product to ship to prospects.

The robotic, known as Vulcan, is a significant step in the direction of making robots much less sausage-fingered in comparison with human beings. Honing robots’ tactile skills additional might permit them to tackle extra success and manufacturing work within the years forward.

Aaron Parness, Amazon’s director of robotics AI who led the event of Vulcan, explains that contact sensing helps the robotic push gadgets round on a shelf and determine what it’s after. “If you’re attempting to stow [or pick] gadgets in one among these pods, you possibly can’t actually try this job with out making contact with the opposite gadgets,” he says.

The Vulcan system consists of a traditional robotic arm with a customized spatula-like appendage for poking right into a shelf, and a sucker for grabbing gadgets to drag them out.

Vulcan has sensors on a number of of its joints that permit the robotic to detect the sting and contours of things. Parness says that machine learning is essential to creating sense of the sensor indicators and in addition varieties a part of the algorithmic loop that controls how a robotic takes actions. “The particular sauce we have now is the software program interpretation of the pressure torque, and the way we wrap these into our management loop and into our movement plans,” he says.

Amazon revealed Vulcan at a success middle in Hamburg, Germany at the moment. The corporate says the robotic is already working at this facility and one other in Spokane, Washington.

The brand new robots will work on the identical line as human pickers, and can purpose to spare them from back-aching work by greedy extra gadgets from cabinets which are excessive up or low down. Gadgets that the robotic decides it can not discover might be reassigned to human employees.

“Amazon shops many various merchandise in bins, so rummaging is important to drag out a particular object to fill an order,” says Ken Goldberg, a roboticist on the College of California, Berkeley. “Till now this has been very troublesome, so I am curious to see the brand new system.”

Goldberg says that analysis on robotic contact sensing has superior lately, with quite a few teams engaged on joint and floor sensing. However he added that robots have some technique to go earlier than they will match the tactile skills of flesh-and-blood employees. “The human sense of contact is extraordinarily delicate and sophisticated, with an enormous dynamic vary,” Goldberg says. “Robots are progressing quickly however I would be stunned to see human-equivalent [skin] sensors within the subsequent five-to-ten years.”

Robotic coworkers

Even so, Vulcan ought to assist automate extra of the work at present achieved by people inside Amazon’s huge empire of success facilities. The corporate has ramped up automation lately with AI-infused robots able to grabbing and transporting packages and packed packing containers. Stowing and retrieving gadgets from cabinets is likely one of the more difficult jobs for robots to do, and it’s closely depending on human labor.

Parness says he doesn’t foresee robots taking up the entire work achieved inside Amazon’s success facilities. “We do not actually imagine in 100% automation, or lights out success,” he says. “We will get to 75 % and have robots working alongside our staff, and the sum could be better [than either working alone].”